Copyright: © 2024 by Alipenhani, Majdi, Bakhshandeh Amnieh and Amini. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY) (

Creative Commons Attribution 4.0 International License). The use, distribution or reproduction in other forums is permitted, provided the original author(s) or licensor are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

1. Introduction

Block caving is one of the most commonly used methods in underground metal exploitation. One of the chief advantages of this method is the ability to use mechanized and automation with high efficiency. The main goal of block caving is mass mining with the lowest operational cost. In the block caving method, since the roof above the undercut is unsupported, by reaching the critical hydraulic radius, it collapses and caves in under its weight. Brown [] defines hydraulic radius as “the ratio of the surface area to the perimeter of an excavated surface”. Due to the gradual upward expansion of the ore block fracturing, the height of the caving zone (HC) increases, which may eventually may cause ground surface subsidence. The Caving zone and the caving height refer to caved or broken material and height of cave back due to undercutting, respectively [].

Nowadays, the main concern of underground mining researchers is to develop a suitable method to evaluate the cavability of the rock mass, the dimensions of the undercut, and the height of the caving zone, which is also the main goal of this research. To investigate these parameters, researchers have used analytical, empirical, numerical, probabilistic, and artificial intelligence methods to date. The history of these methods has been fully detailed by Alipenhani et al. [2–4]. In this paper, only the analytical methods related to the cavability of the rock mass are considered. Rice [] and Panek [] developed a one-dimensional volumetric method to investigate the properties of caving propagation behavior, taking the volume expansion factor into account (). Today, simple volumetric relationships are still used by several researchers to estimate the caving propagation rates. Among these studies, are works conducted by Ross and Van [], Carlson and Golden [], and Beck et al. []. The assumptions considered in this method are: 1) caving initiation (process initiation of natural caving by undercutting) always occurs, 2) caving propagation (process of propagation of an initiated cave by progressive drawing of broken ore) is always vertical, and 3) the caving rate is constant. Fu et al. [] conducted a numerical study using ANSYS software to analyze the height of the caving zone in the Shangwan Coal Mine. They concluded that the height of the caving zone increases with the working face length and working face height. Song et al. [] found that the height of the caving zone is more affected by working face length than working face height. The location of the coal and the primary key stratum also significantly influence the height of the caving zone [,]. Majdi et al. [] calculated the height of the destressed zone (a combination of the caving zone and the fractured zone) above a longwall panel analytically. They determined the height of the destressed zone based on the height of the mined coal seam and the volume expansion factor by assuming different shapes for the destressed zone in 2D. In the aforementioned analytical methods, very few details of geomechanical conditions have been investigated. Somehneshin et al. [] used an analytical method to determine the optimal width and length required for caving. They employed the shear strength criterion of the rock mass. Thus, caving continues until the total weight of ore and waste above the undercut roof overcomes the shear strength of the rock mass. A tensile strength criterion provides a more accurate estimate of caving height for rock masses with lower tensile strengths than their shear strengths, which is one of the caving mechanisms. As tensile failure is a common caving mechanism, a tensile strength criterion can provide an appropriate estimate of caving height. Based on plate theory, Xia and Tan [] investigated the mechanism of stress and displacement at the extraction level. The height of the caving zone was not considered in their investigations. Zhou et al. [] determined the height of the caving zone in a coal mine using numerical simulation and the LK-Means Algorithm. The results illustrated that the height of the caving zone was close to those obtained in the field tests. Zhang et al. [] calculated the height of the caving zone in a coal seam using field measurements, theoretical analysis, and numerical simulation by. The results depict that the mentioned methods are consistent to a certain degree. Alipenhani et al. [] developed three mathematical models to calculate the height of the caving zone in two dimensions and discontinuous environment based on the shape of the caving from physical experiments. According to the views mentioned above, there is currently no mathematical model that can calculate the caving height in three dimensions based on the geomechanical and geometric characteristics of the undercut. An analytical equation that can calculate the height of the caving zone in a simple and accurate manner for pre-feasibility studies has not yet been developed.

Predicting the height of the caving zone is important for several aspects of the conceptual design of block caving mines in the early stages of design and decision-making when the level of rock mass data is available. First, the height of the caving zone shows how the caving will propagate due to undercutting and whether it will reach the top level of the ore block. Additionally, the height of the caving zone can help calculate the volume of mineable ore in the early stages of pre-feasibility studies. Based on this, in this paper, the height of the caving zone is calculated using two simple and practical approaches based on tensile strength and the broken rock expansion factor. The relationship between the height of the extracted caved ore (tc), the height of the in-place ore extracted (ti), and the height of the cave back (∆h) showed in .

2. Mathematical modeling

There are different methods to determine the cavability of the rock mass in the block caving method. Research in this field is mostly based on the hydraulic radius of caving. Empirical graphs, physical modeling, numerical modeling, and mathematical modeling are methods that can be used to estimate the height of the caving zone. Although empirical methods are very simple and easy to use, they largely depend on personal judgment in the classification of the rock mass. Physical modeling requires significant costs and time. However, the other two methods—numerical and mathematical—are simple, inexpensive, and can produce very useful and reliable results.

In this research, according to the caving initiation and propagation mechanism, four mathematical models have been proposed based on the tensile failure criterion and the expansion factor, which will be explained below.

2.1. Cubic caving zone model

In this model, it is assumed that the length and width of the caving zone are equal to the length and width of the undercut. In other words, tensile failure occurs at the top four corners of the undercut. This method can be employed when boundary slots are created at both ends in advance. In this case, it is assumed that the block is in one piece. shows the geometry of the problem considering the cubic shape model for the caving area. In , HC is the height of the caving zone and HU is the height of the undercut Since most of the undercuts are rectangular in the block caving method, the corresponding undercut in the cubic model is also assumed to be rectangular. In this model, length of the undercut “X” is considered to be as a factor “a” of its width “Y”. This factor is greater than one.

The only force that acts on the undercut roof is due to the weight of the caving column (WC). Therefore, to initiate caving and to propagate it upwards, the weight of the caved ore column must be greater than the tensile strength (σt) of the orebody. Hence, one can write the following equation:

Weight of the caving zone can be computed by using the dimensions of the block. To normalize the units, tensile strength is multiplied by the area. Equation (1) can further be written based on the dimensions of the caving area, unit weight, and expansion factor of broken ore. It is assumed that the cross-sectional area of the broken ore "α" times the area of the caved zone similar to that given by Majdi et al. [], then Equation (1) can be rewritten as follows:

Thus, using Equation (4) and Equation (5), the height of the caving zone can be calculated.

2.2. Prismatic caving zone model

In this model, it is assumed that the shape of the caving zone is similar to a prism as shown in . Using boundary conditions similar to the cubic model, then the height of the caving zone can be estimated by the following equations:

In this case, by using Equation (6), height of the caving zone above the undercut roof with a circular footprint and a prism shape can be easily estimated.

2.3. Hemispheric-shaped caving zone model

In this model, it is assumed that the shape of the caving zone is similar to a hemisphere as shown in . This shape of caving zone may occur in soft rock masses such sedimentary rock. Similar to the prismatic model, the weight of the undercut roof caved ore must overcome the corresponding tensile strength. Therefore, the height of the caving zone can be estimated by using the following equations:

Equation (8) and Equation (9) can also be applied to the half-elliptical caving zone model.

2.4 Parabolic-shaped caving zone model

In this model, it is assumed that the caving shape follows a parabolic function as shown in . Therefore, its volume is equal toπX(aX)HC/2 according to the previous proof, the height of the caving zone can be calculated by using the following equations:

2.4 Average height of caving zone

It is possible to calculate the minimum height of the caving zone using the above equations (Equation (3) and Equation (5) to Equation (11)) regardless of the shape of the caved zone. In this case, using one of the models presented in this paper, it is also possible to calculate the volume of caved ore and evaluate the shape of the caving zone. Economic indexes are highly dependent on the calculation of the caved ore’s volume. Using one of the models that show the shape of the caving zone, the volume of the caving zone can be calculated.

An average of the presented equations can simplify calculation of the height of the caving zone, as follows:

(12)

(11)

where Hc.avg is the average height of the caving zone (in meter). Using Equation (12) and Equation (13), the minimum height of the caving zone can easily be calculated.

3. Results and discussion

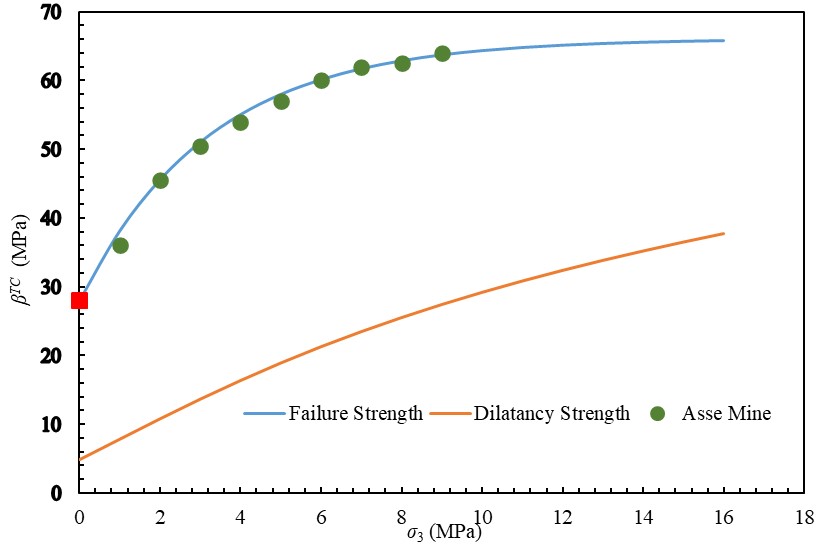

A comparative study of the results obtained from four new equations to estimate the height of the caving zone in 3D mode (HC) is presented. The results are compared with the equations presented by Majdi et al. []. The changes in the height of the caving zone against tensile strength, uniaxial compressive strength of the rock mass (the uniaxial compressive strength is considered to be 12 times of the tensile strength), unit weight, undercut height and expansion factor are shown in , , , , , , , , , , , , , , .

These models have limitations, such as not considering the influence of horizontal stresses and assuming that the rock mass is continuous. Additionally, the model requires the use of average geomechanical properties for layered materials. Future research could address these limitations by considering stratum, discontinuity, and horizontal stress. In this paper, the values of unit weight, tensile strength of the rock mass, undercut height and expansion factor are given in . These values have been deduced by investigating the data of different mines.

As shown in to and to , in cubic, prismatic, hemispheric and parabolic models, there is a linear relationship between HC and the strength parameters such as: tensile and uniaxial compressive strength of the rock mass and the undercut height as well. In other words, the height of the caving zone is higher for stronger rock masses. It is consistent with the results that obtained by Peng []. According to Peng [], the combined height of the caving and fractured zones is generally 20 to 30 times the extraction height, which is higher for hard strata. According to the models proposed in this paper, the height of the caving zone for the cubic, prismatic, hemispheric and parabolic models for the expansion factor of 0.1 is 10, 30, 15 and 20 times the undercut height, respectively. On average, the height of the caving zone is 18.8 times the undercut height. These values for the expansion factor of 0.4 are 2.5, 7.5, 3.8 and 5 times the undercut height, respectively. Also, the height of the caving zone for the cubic, prismatic, hemispheric and parabolic models for the unit weight of 27 kN/m3 is 37, 111, 55.5 and 74 times the tensile strength of the rock mass, correspondingly. Averagely, the height of the caving zone is 69.5 times the tensile strength.

The height of the caving zone for the cubic, prismatic, hemispheric and parabolic models for the unit weight of 27 kN/m3 is 3, 9.3, 4.6 and 6.2 times the uniaxial compressive strength of the rock mass. On average, the height of the caving zone is 5.8 times the uniaxial compressive strength.

According to Majdi et al. [], the mathematical model (similar to Majdi et al. [] arithmetic model) shows a nonlinear relationship between HDZ (height of the destressed zone) and the height of the extracted coal seam. For the mentioned mathematical model, the ratio (HC/hs) is not constant. According to the other models presented in this paper and the equations presented by Majdi et al. [] there is a linear relationship between the caving height and the undercut height.

As shown in to and to , the height of the caving zone has an inverse relationship with the unit weight of the roof material and also the expansion factor of the material. In to , the results compared with Majdi et al. [] five different Models: a) arithmetic model, b) geometric sequence model, c) parabolic model, d) elliptic model, and e) triangular model. For more information, you can refer to Majdi et al. []. As it is clear in to , the hemispheric and parabolic models are the same as Majdi et al. [] parabolic and triangular models.

The height of the caving zone of the proposed cubic, prismatic, hemispheric and parabolic models for the tensile strength of 1.5 MPa (uniaxial compressive strength of 18 MPa) is, respectively, expressed by the equations of . On average, the height of the caving zone in this case can be calculated from the Equation (18) in .

The height of the caving zone for cubic, prismatic, hemispheric and parabolic models for the undercut height of 4 meters is expressed by the equations of , respectively. On average, the height of the caving zone in this case can be calculated from the Equation (23) in .

4. Conclusions

In this research, four new mathematical models have been proposed to estimate the height of the caving zone based on different shapes of the caving zone. The results were analyzed and compared with the equations presented in the literature. The model's results are consistent with those obtained from previous research. In the presented models, the mechanical properties (tensile strength and compressive strength of rock mass) have been used, making their use possible in pre-feasibility studies. The practical finding are as follows:

The results showed the height of the caving zone is, on average, 18.75 times the undercut height, 69.5 times the tensile strength of the rock mass, and 5.8 times the uniaxial compressive strength of the rock mass. The sensitivity analysis results indicate that the height of the caving zone is directly linearly related to the undercut height, uniaxial compressive strength, and tensile strength of the rock mass.

The average height of the caving zone can be calculated by dividing 2812.5 by the unit weight of the rock mass or by dividing 7.5 by the expansion factor of the rock mass. Additionally, the sensitivity analysis results show that the height of the caving zone has a logarithmic relationship with the unit weight and expansion factor of the rock mass.

The height of the caving zone can be calculated as 1.9 times the ratio of the tensile strength of the rock mass to its unit weight or 1.9 times the ratio of the undercut height to the expansion factor of broken ore. Given the variable behavior of the rock mass due to undercutting, it is advisable to consider the average of different states to account for real conditions. In other words, the average coefficients have been utilized to simplify the application, aligning with the general trend of the results.

Author contributions

Conceptualization, A.M; methodology, B.A; validation, B.A, formal analysis, B.A; investigation, B.A; data curation, B.A; writing — original draft preparation, B.A; writing — review and editing, E.A; visualization, E.A; supervision, A.M and H.B.A; project administration, A.M and H.B.A. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

No funding was received to assist with the preparation of this manuscript.

Conflicts of Interest

All the authors claim that the manuscript is completely original. The authors also declare no conflict of interest.

Data availability

All relevant data related to this manuscript are available and can be provided upon reasonable request.

Fig. 1. Caving process (after Sainsbury [20]).

Fig. 2. 3D view of the cubic caving zone.

Fig. 3. 3D view of the prismatic caving zone.

Fig. 4. 3D view of the hemispheric-shaped caving zone.

Fig. 5. 3D view of the parabolic-shaped caving zone.

Table 1. Values used for unit weight, tensile strength of rock mass, undercut height and expansion factor

Fig. 6. The relationship between the height of the caving zone and the tensile strength of the rock mass for the unit weight of 22 kN/m3.

Fig. 7. The relationship between the height of the caving zone and the tensile strength of the rock mass for the unit weight of 27 kN/m3.

Fig. 8. The relationship between the height of the caving zone and the tensile strength of the rock mass for the unit weight of 33 kN/m3.

Fig. 9. The relationship between the height of the caving zone and the uniaxial compressive strength of the rock mass for the unit weight of 22 kN/m3.

Fig. 10. The relationship between the height of the caving zone and the uniaxial compressive strength of the rock mass for the unit weight of 27 kN/m3.

Fig. 11. The relationship between the height of the caving zone and the uniaxial compressive strength of the rock mass for the unit weight of 33 kN/m3.

Fig. 12. The relationship between the height of the caving zone and the unit weight in the tensile strength of 0.1 MPa.

Fig. 13. The relationship between the height of the caving zone and the unit weight in the tensile strength of 1.5 MPa.

Fig. 14. The relationship between the height of the caving zone and the unit weight in the tensile strength of 3.5 MPa.

Fig. 15. The relationship between the height of the caving zone and the height of the undercut for the expansion factor of 10%.

Fig. 16. The relationship between the height of the caving zone and the height of the undercut for the expansion factor of 40%.

Fig. 17. The relationship between the height of the caving zone and the height of the undercut for the expansion factor of 80%.

Fig. 18. The relationship between the height of the caving zone and the expansion factor for the undercut height of 4 m.

Fig. 19. The relationship between the height of the caving zone and the expansion factor for the undercut height of 10 m.

Table 2. Equations for calculating the caving height in terms of unit weight for tensile strength of 1.5 MPa.

Fig. 20. The relationship between the height of the caving zone and the expansion factor for the undercut height of 10 m.

Table 3. Equations for calculating caving height according to expansion factor for undercut height of 4 m.