1. Introduction

Dimension stones, defined as natural rocks carefully extracted and processed to meet specific architectural and construction requirements, play a vital role in both local and global markets. These stones find extensive applications in a myriad of settings, including external walls, flooring, ornamental features, staircases, and pathways, significantly enhancing the aesthetic appeal and functionality of buildings []. The economic importance of assessing dimension stones in Ethiopia is underscored by the potential for these resources to not only bolster local economies through job creation and infrastructure development but also contribute to the global stone market, where demand for high-quality materials continues to rise.

Historically, Ethiopia has a rich heritage of utilizing stone as a primary construction material, as demonstrated by iconic structures such as the Obelisk of Axum, carved from granite; the St. George Churches of Lalibela, crafted from ignimbrite; and the Temple of Yeha, composed of sandstone [,,]. These historical uses highlight the cultural significance of dimension stones, while contemporary applications reflect the ongoing relevance of these materials in modern architecture and construction. However, the dimension stone industry is not without its challenges. Issues such as inefficient extraction methods, environmental impacts, and a lack of standardized processing techniques hinder the growth and sustainability of the sector. Addressing these challenges is essential for improving the quality of dimension stone production and enhancing its marketability.

Dimension stones, often referred to as ornamental stones, provide unique aesthetic qualities that contribute to the visual appeal of contemporary structures. Selecting the appropriate dimension stone involves careful consideration of key factors such as color, texture, size, and overall pattern, along with the stone's strength, resilience, and polish. The most commonly utilized types of dimension stones include slate, granite, sandstone, marble, and limestone, with lesser-known varieties like greenstone, serpentine, alabaster (massive gypsum), and soapstone also included in this category.

The market potential of dimension stones is largely dictated by their geological origins, which can be classified into three main categories: metamorphic, igneous, and sedimentary rocks. To fully assess this potential, it is crucial to evaluate both the mechanical properties such as color, grain size, and texture and technical features, including petrography, mineralogy, brittle deformation, physico-mechanical tests, and available volumes. The interplay between mechanical and aesthetic qualities significantly influences a stone's marketability. Enhanced technical characteristics are pivotal in determining the performance and suitability of dimension stones for various applications, whether in indoor or outdoor settings and under diverse environmental conditions such as exposure to sunlight, pollution, chemicals, grease, or oil. Recent advancements in testing methodologies, such as ultrasonic testing, have proven effective in ensuring the selection of high-quality dimension stone blocks []. Furthermore, the integration of predictive modeling, particularly through machine learning techniques, has improved the ability to forecast the durability of natural stones [].

The global dimension stone industry is expansive, with over 50 major countries involved in the production, export, and consumption of stone products. Leading producers, including Brazil, China, India, Italy, and Spain, boast annual production levels ranging from nine to over twenty-two million tons, while Portugal contributes approximately three million tons annually. The United States holds the largest market share worldwide.

Despite Ethiopia's rich historical utilization of stone, geological exploration for industrial dimension stone production remains limited. The Ethiopian Geological Survey has identified significant resources of marble, limestone, granite, and sandstone [] and has actively invited domestic and foreign investments in quarry development and exploration. Consequently, several local and international mining companies have received permits for granite, marble, and limestone extraction across various regions of the country. The production landscape features marble quarries in the west and north, while granite quarries in the northeast, northwest, and east yield commercial blocks measuring approximately 2.4 x 1.2 x 1 m, or around eight tons. Additionally, processing companies operate multiple stone fabrication plants, often distanced from their quarry sites, exemplified by the National Mining Company (NMC) based in Awash, Central Ethiopia, with quarries situated in the east and west of the country. The two largest dimension stone companies, Semayata and Saba Dimensional Stone Plc, are located in the Tigray region, in the towns of Wukro and Adwa, respectively, also far from their quarry sites.

Among the various dimension stones, white marble has witnessed a notable increase in demand from designers and businesses, reflecting an ongoing trend in both domestic and global markets. This study was prompted by the growing interest in marble and granite resources for dimension stone production. The research emphasizes geological, petrographic, and physicomechanical tests to evaluate key parameters such as color homogeneity, texture uniformity, block size, deposit characteristics, impurity content and distribution, and other essential factors for producing commercially viable dimension stones. By addressing the current challenges in the industry and proposing innovative solutions, this research aims to enhance the sustainability and efficiency of dimension stone production in Ethiopia, ultimately contributing to the growth of the sector and its economic viability.

2. Geological overview

2.1. Geological setting

The basement rocks in northern Ethiopia are of Neoproterozoic age and form the southern end of the Arabian Nubian Shield (ANS). They consist of low-grade metavolcanic, metavolcanoclastic, and metase-dimentary rocks, along with syn-late-tectonic granitoids and younger mafic and felsic dykes. These rocks are related to the Upper Complex [,,] of Ethiopian stratigraphy. They are divided into two major lithostratigraphic groups, namely the Tsaliet and Tambien Groups ( and ). The Tsaliet Group is older and dominated by low-grade metavolcanic and metavolcaniclastic rocks, varying in composition from mafic to felsic. Its thickness reaches up to 1500 m and is unconformably overlain by the Tambien Group, which is dominated by metasedimentary rocks approximately 2000 m thick. These represent two facies: (i) Mai Kenetal Facies, composed of four formations (Werei slate, Assem limestone, Tsedia slate, and Mai Kenetal limestone), and (ii) Negash Facies, composed of slate, meta limestone, and siliceous dolomite.

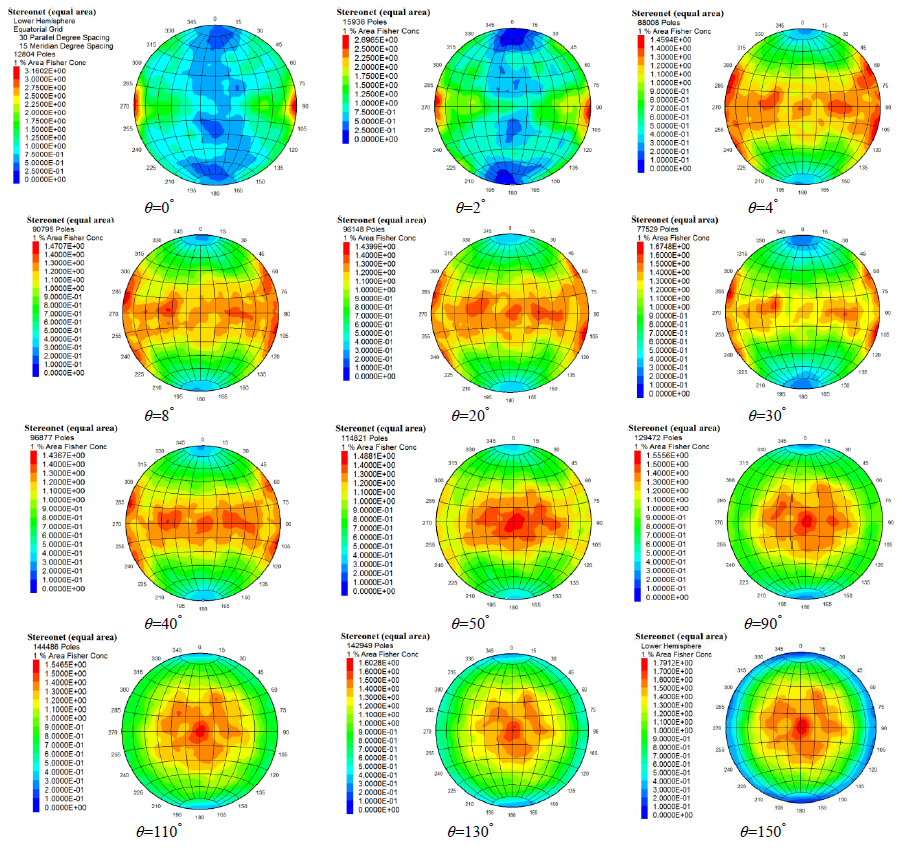

Firstly, each joint profile image was captured using screenshot software and saved as a JPG file. Next, non-essential pixels were removed, and the horizontal and vertical axes were defined for each image. The original lengths of the ten joint profiles varied slightly, ranging from 96 mm to 101 mm [,]. To ensure consistency in experimental research, all profiles were adjusted to a uniform horizontal length of 100 mm, with their JRC values assumed to remain unchanged. This procedure aligns with the methods recommended by other researchers [,,]. Finally, the geometric coordinates of the ten joint profiles were obtained using both automatic acquisition and point capture modes, with data points placed at the center of each profile. This approach is consistent with the method described by Jang et al.[], as illustrated in . The modified standard roughness profiles are shown in . The JRC values for these profiles, when sheared from left to right, match Barton's inverse calculation: 0.4, 2.8, 5.8, 6.7, 9.5, 10.8, 12.8, 14.5, 16.7, and 18.7, respectively.

The pre- or syn-tectonic granitoids intruded the Tsaliet Group at about ~800 to 735 Ma, whereas the post-tectonic granitoids intruded the Tambien and Tsaliet groups as well as the diamictites between ~620 and ~520 Ma [,]. The late to post-tectonic granitoids are found intruding the low-grade metavolcanic sedimentary units in the ANS and the gneissic terrain in the Mozambique belt of Ethiopia.

2.2. Application of dimension stone

Dimension Stone is widely used in exterior and interior applications, such as slabs for flooring and wall tiles in public and commercial buildings, and monuments. Basalt and granite are often used to build foundations due to their abundance. Polished marble and granite are also popular for kitchen countertops because of their high durability and aesthetic qualities. In architecture and countertops, the term "granite" often refers to igneous rocks that contain large crystals, rather than specifically to those with a granite composition []. In some areas, granite, marble, and limestone are used for tombstones and monuments. Granite and marble are hard stones that require skill to carve by hand []. Modern engraving methods include the use of computer-controlled rotary drills and sandblasting onto rubber templates. The blaster emits letters, numbers, and emblems onto the stone, allowing for the creation of virtually any type of artwork or inscription. Large quantities of stone are used in the construction industry. For the exterior of civil and office buildings, polished panels with a thickness of 2 cm are used []. Marble and granite can be cut into floor tiles (30 cm x 30 cm) and countertops for use in shopping malls, hotels, and even individual homes []. Granite curbs and cobblestones are used as urban road surfaces because of their durability [].

3. Methodology

3.1. Methods

The methodology of this study involved both field and laboratory analyses [,]. During the fieldwork, detailed geological mapping was carried out at each site, and representative samples were collected from both quarry locations and surface rocksc []. Approximately 2 kg of each rock sample was collected, taking into account lithological variations []. Specifically, 1 kg of granite and marble samples were collected based on observable lateral and vertical variations in color, grain size, and texture within the exposed deposits []. A systematic sampling approach was used, as the deposits were not randomly distributed []. Most samples were taken from quarry sites, as surface samples are more prone to contamination []. Alongside sample collection, lithological identification and geological mapping were key tasks []. Geological exposures were recorded along hillsides, quarry sites, local mining excavations, and riverbanks []. Samples were selected based on lithological variability and the occurrence of granite and marble resources [].

A total of 30 samples were prepared for analysis: 15 from marble and 15 from granite []. Of these, 15 were designated for petrographic analysis and 15 for physico-mechanical testing []. The samples were examined at the central petrographic laboratory of the Geological Survey of Ethiopia in Addis Ababa and the geotechnical laboratory of the Ethiopian Construction Design and Supervision Works Corporation []. These analyses were crucial in determining the mineralogy, grain size, texture, fabric, and weathering states of the rocks, which are influenced by geological processes and affect how a rock may fail []. This information is vital for optimizing the production of high-quality dimension stone and terrazzo resources [].

Physico-mechanical tests, including physical tests (density, porosity, water-soluble matter, and luster) and mechanical tests (flexural strength, compressive strength, abrasion resistance, water absorption, polishing surface appearance, and hardness), were conducted to assess the suitability of the granite and marble resources for dimension stone and terrazzo production [].

3.2. Materials

Various materials were utilized during the study, including previous geological, geochemical, and structural maps of the surrounding area []; a computer; a digital camera; topographic maps; satellite imagery; and geological field equipment such as GPS, hammers, notebooks, Burton compasses, and plastic bags []. Other materials included a printer, scanner, and office supplies []. For data processing, software like ArcGIS v10, Global Mapper v12, and CorelDraw X4 was employed [].

4. Results and Discussion

4.1. Physico-mechanical properties

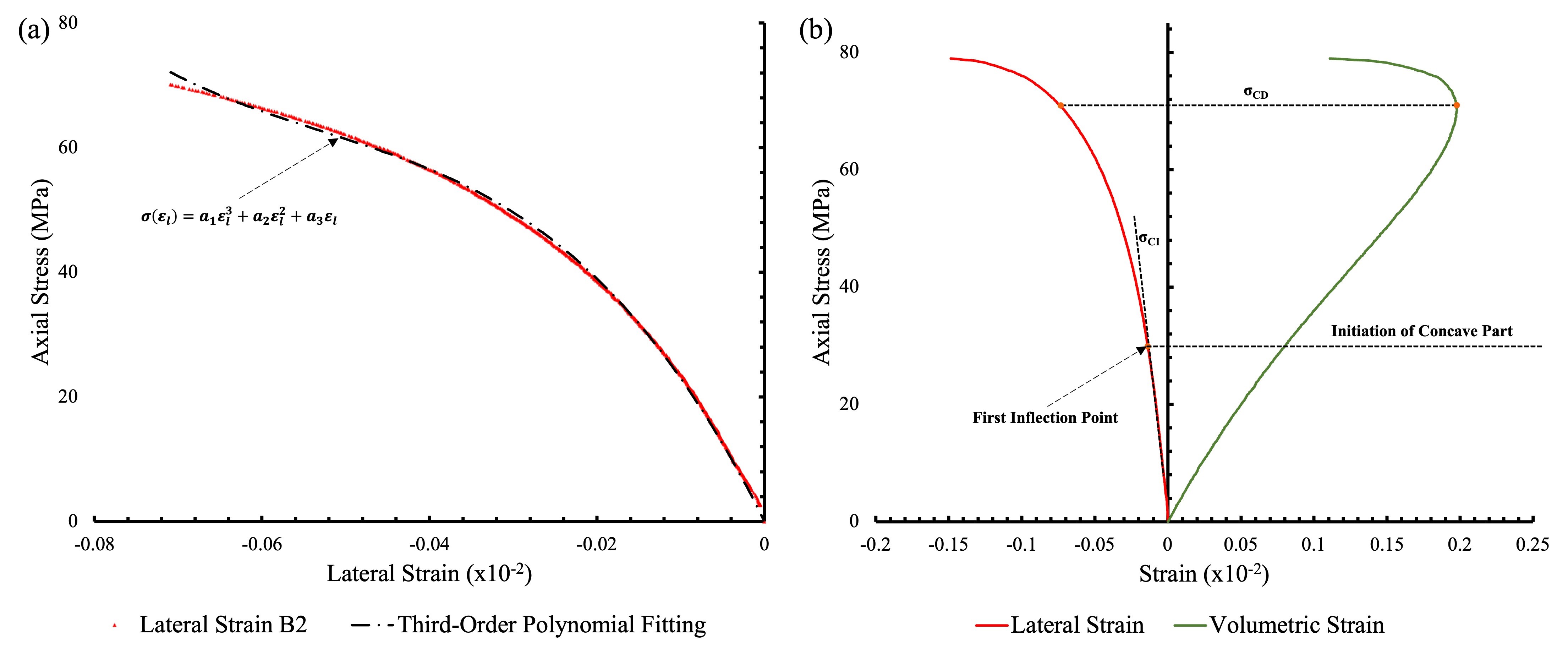

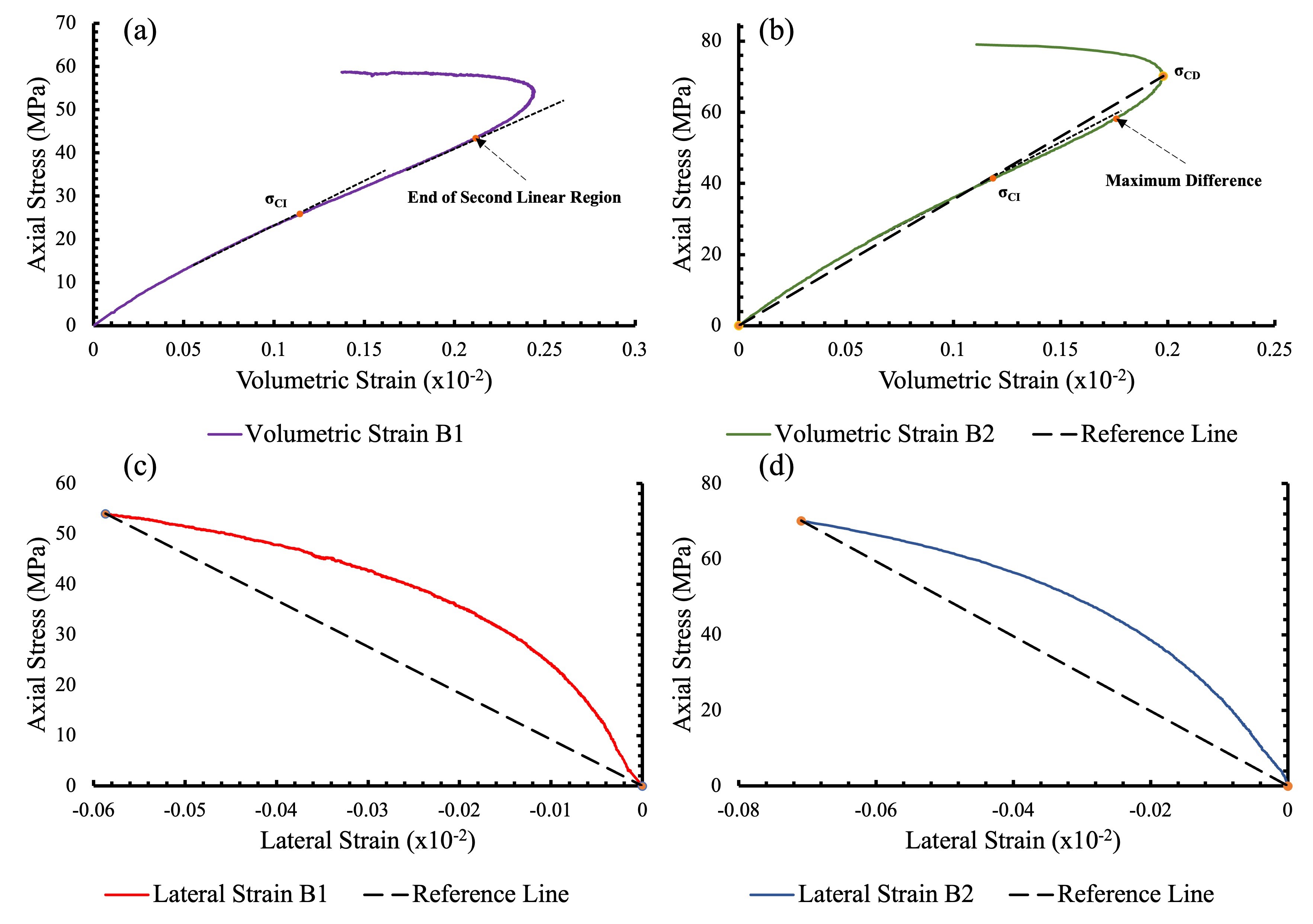

The physico-mechanical properties of granite and marble are essential for determining their suitability in various construction and industrial applications. These properties help assess the strength, durability, and usability of the stone under different environmental and load conditions. summarizes the results of the physical and mechanical tests conducted on the studied granite and marble samples. The key parameters evaluated include density, porosity, water absorption, uniaxial compressive strength, tensile strength, and hardness (). These values offer insight into the performance of the stone in structural applications and can help inform decisions regarding their use in building materials, flooring, and decorative purposes.

4.1.1. Porosity

Porosity is the ratio of the volume of pores to the total solid volume of a material and was measured according to the methods described by Nover et al. [] and Harrison []. Although marble has a relatively low porosity, it can absorb small amounts of moisture and other liquids, which may lead to corrosion or staining []. Additionally, exposure to water and acid rain can negatively impact the appearance and durability of marble over time []. The weight of the dried sample (W.) and then saturated with water was weighed in water (W1), and weight in air (W2), with the porosity (P) calculated as follows: P=W2-W/W2-W1 x 100 []. Granite has a porosity ratio between 0.4% and 1.12% []. This porosity ratio is confirmed by the visual porosity (intercrystallite and micro-porosity) []. In metamorphic rock, porosity appears as micro-voids during the re-crystallization process. In marble, the porosity ratio varies between 0.57% and 1.98% as indicated in .

4.1.2. Density

The representative samples of granite were measured according to ASTM D 153 [], and the results ranged from 2.65 to 2.739 g/cm³ as indicated in Table 1; according to the standard, low specific gravity is preferred for paper manufacture []. To understand the correlation of each sample with the physical and mechanical properties, this study introduced a Pearson correlation plot () []. Consequently, shows the histogram probability plot of all physical and mechanical testing results of granite and marble [].

4.1.3. Matter Soluble in Water

The granite and marble powder are generally insoluble in water, except for traces of soluble salts. Test results indicate that the amount of soluble matter for marble ranges from 0.36% to 0.5%, and for granite, it ranges from 0.12% to 0.34%, as shown in . According to ASTM D 2196 (1987), the maximum limits are 0.4% for marble and 0.25% for granite [].

4.1.4. Luster

Luster refers to the appearance of a mineral surface in reflected light, influenced by the transparency, refractivity, and structure of the mineral. The luster of granite varies from dull to grainy, with sporadic parts appearing pearly and vitreous. In contrast, marble exhibits a luster that ranges from whitish to cloudy [].

4.1.5. Compressive Strength

The primary objective of the compressive strength test is to ensure that granite and marble can withstand external forces and shocks that may occur during installation and transportation, as outlined by Gaber (1995) and ASTM C 170 (2017) []. The procedure for measuring compressive strength is illustrated in , and the results are presented in [].

4.1.6. Flexural Strength

Flexural strength is useful in indicating the differences between granite and marble. It is determined using a simple beam with quarter-point loading. Tests on rocks should be conducted when relevant to the situation, with loads applied perpendicularly and parallel to the bedding plane, as per ASTM C 880 (1979) [].

4.1.7. Abrasion

The abrasion resistance test was conducted on the studied samples to assess the percentage of weight loss after 352 revolutions. The abrasion loss of thickness was calculated according to M.A. Abd El–Hamid et al. (2015) using the formula W1−W2A⋅p\frac{W1-W2}{A\cdot p}A⋅pW1−W2, where W1W1W1 is the weight of the specimen before abrasion, W2W2W2 is the weight after abrasion, ppp is the sample density, and AAA is the cross-sectional area of the specimen. The results are indicated in [].

4.1.8. Water Absorption

The water absorption of solid and massive samples of granite and marble is determined according to ASTM C 128 (1979), ASTM C 642 (1982 Modified), and ASTM C 97 (2015) []. Water absorption is calculated from the formula c−xc×100\frac{c - x}{c} \times 100cc−x×100, where ccc is the saturated weight and xxx is the dry weight. The water absorption coefficient provides an indication of the porosity and water permeability of the material, revealing any cracks or fissures within the concrete coating. According to Gaber (1995), water absorption should be less than 5% based on standard specifications [].

4.1.9. Polishing Surface Appearance

Marble can be polished to a high luster after being sanded with fine abrasive tools. This process enables attractive pieces of marble to be cut, polished, and utilized as floor tiles, architectural panels, facing stone, windowsills, stair treads, columns, and other decorative stone applications, as noted by M. Fakhry et al. (2016) [].

4.1.10. Hardness

Hardness refers to a mineral or rock's resistance to abrasion or scratching, described in terms of Moh’s scale. This scale consists of ten minerals arranged in order of increasing hardness, from talc to diamond. Granite exhibits high hardness due to the presence of quartz, while marble, composed mainly of calcite, has a hardness of three on the Mohs hardness scale. The lower hardness of marble compared to granite affects the abrasion and polishing process during the cutting of decorative stones into their final shapes [].

4.2. Geology and petrography of dimension stone in Tigray

Wide varieties of rocks are used as dimension stones in Tigray. However, the common ones are associated with Precambrian metamorphic and igneous rocks, which are exposed in the peripheral part of the region, due to the removal of overlying materials by erosion. So, more potential marble deposits occur in the Dichinama, Dugub, Elawedizeray, Adigolagool, Kelafinos, Newi, Enda-Tikur, Naedir and Berdada areas. Similarly, granites of Proterozoic to Early Palaeozoic age, occur as intrusive bodies within these metamorphic rocks. Deposits of such types occur in Negash, Adi Elena, Adikelete, Kisad Gaba, Embamadr, Adiet, and Sebeya areas. Thick successions of Palaeozoic sediments include building stone quality of limestone also occur predominantly. The upper part, however, is in places calcareous, particularly close to the transition to the overlying limestone of the Antalo Group. Thick limestones are developed in the middle part of this group, varying from near shore, oolithic limestones, through fossiliferous, pale limestone and marl to black limestone deposited in deeper water. Messobo, Togogo areas are among the predominant exposures of limestone.

4.2.1. Granite

It is derived from the Latin granum (grain) and refers to the coarse-grained plutonic rock of a specific composition that contains plagioclase, orthoclase, and quartz as the main minerals. However, in the dimensional stone trade, the term refers to a wide range of hard siliceous rocks, including closely related plutonic rocks such as granodiorite and tonalite, as well as less related plutonic rocks. It also includes metamorphic rocks such as gabbro, monzonite, and even gneiss []. Granite typically has a medium to coarse-grained texture. In some cases, individual crystals (phenocrysts) can be larger than the groundmass. The texture in this case is called porphyry. Granite with a porphyry texture is sometimes called porphyry. The color of granite varies from pink to gray, depending on its chemical and mineralogical properties. Granite produces different outcrops due to weathering and rounded massifs. Granites may occur in circular depressions surrounded by a series of hills formed by metamorphic halos and hornfels. Granite occurs in the continental plates of the Earth's crust and is often used as a building stone because it is solid/denser (2.65-2.75 g/cm³), hard (compressive strength 200 MPa), and durable (viscosity 3-6 × 10¹⁹ Pa). This rock type is stable and common in the continental crust, i.e., often produced in relative stocks of <100 km² and in batholiths (associated with orogens) as well as aplitic dykes (associated with the margins of granite intrusions), which underlies the relatively thin sedimentary layers of the continents.

In some places, very coarse-grained pegmatite clasts occur alongside granite. Granite has invaded the Earth's crust during all geological periods, but most date back to the Precambrian period. Granite has a variety of uses as a dimensional rock (as curbstones, cobblestones, granite paving stones, landscaping stones, granite slabs, granite stairs, monuments, gravestones, millstones, and other building products). Physical appearance (color and texture) is the major factor in determining the commercial quality of granite, but homogeneity is also critical, i.e., it must be free from inclusions (veins, veinlets, and xenoliths). The known deposits occur around Negash, Adi Eleni, Adikelete, Borpuah, Kisadgaba, Embamadre, and Sebeya granite deposits ().

Petrographically, the analyzed samples are dominated by orthoclase feldspar, microcline, and quartz, with biotite, muscovite, epidote, and hornblende present as minor minerals. In some granite samples, accessory minerals like epidote and chlorite are also observed. Relict textures, including the breakdown of hornblende and its replacement by feldspars, are present. Furthermore, chloritization (feldspars altered to chlorite) and epidotization (biotite altered to epidote) occur along cleavage traces and grain boundaries. The samples display fine to medium-grained epidote accompanied by interstitial quartz, anisotropic textures, and oblate to curved grain boundaries. The minerals exhibit impression and disequilibrium geometry, indicating contact metamorphism. presents photomicrographs (A, C, and E) of granite thin sections observed under cross-polarized light (XPL), along with field photographs (B, D, and F) of granite exposures. The labeled minerals in these images—Qtz (Quartz), Kfs (Potassium feldspar), Chl (Chlorite), Ms (Muscovite), Bt (Biotite), Ser (Sericite), Orth (Orthoclase), and Pl (Plagioclase)—provide visual evidence of the mineral compositions and textures discussed. These photomicrographs highlight important features such as grain boundaries, relict textures, and mineral alterations, supporting the petrographic observations outlined in the text. The modal mineral proportions are as follows: Kfs ~40%, Qtz ~25%, Pl ~15%, Bt ~11%, and Msc ~4% for sample G-01; Kfs ~47%, Qtz ~23%, Bt ~11%, Pl ~9%, Ep ~5%, Ms ~2%, and Hbl ~1% for sample G-02; and Kfs ~45%, Qtz ~20%, Pl ~20%, Ms ~10%, and Op ~5% for sample G-03.

4.2.2. Marble

Marble is the transformed product of limestone, due to the involvement of heat and pressure, which transforms it into a dense, multi-colored crystallized rock. It is composed primarily of calcite (white color) with small amounts of impurities (silicate minerals distinctive green color; graphite—a dark color, producing a greenish-gray hue; and hematite, which imparts a pinkish hue). Unusual colors such as sky blue are due to impurities or 'defects' within the calcite crystals [,] ( & 9). Large marble deposits have been found in the Precambrian metamorphosed terrain of northern Ethiopia [,]. The known deposits occur around Naeder, Dichenama, Newi, Adiwoyane, Emnizong, Akmara, and Tekeze marble sites. Most of the outcrops are hilly to cliff-forming, white to gray, and fine-grained, predominantly composed of calcite. Pink, greenish, and sky-blue varieties, as well as dolomitic marbles, are also locally present [,] (). The fine-grained, whitish to purple marble resembles the original limestone, possibly due to a lower degree of metamorphism. These characteristics are consistent with the results found by [].

Marble is mined in the Tigray region using both small-scale operations (hand-held hammer drills and wedges) and more advanced methods (blasting or sawing) for various architectural and artistic purposes. The primary cut is supported by natural seams and wedged along vertical and horizontal wellbore lines. Final shaping of the block is accomplished through secondary drilling and wedging. The maximum size of the end block is 1.15 tons, constrained by the load capacity of transport trucks (). Larger commercial blocks are extracted using drilling, blasting, wedging, and diamond sawing methods (). Marble deposits in the Tigray region are exposed in Naeder, Dichenama, Newi, Adiwoyane, Emnizong, Tekeze, and Akmera areas, with their geography, general characteristics, and estimated reserve described in .

From the microscopic point of view, all the analysed samples are characterized by the presence of prevailing calcite crystals. But in some of the thin sections cloudy appearance is observed, this may be due to the presence of both micro-porosities and opaque sub-microscopic inclusions in their interior (). Moreover, all samples also exhibit opaque impurities concentrated on the calcite grain boundaries. Calcite is dominant but also, but feldspars, microcline, muscovite, biotite, and quartz minerals are also recognizable under the microscope (). In addition, some small, isolated grains of both a probable phyllosilicate and an opaque phase are observed which is reddish to reflected light. Textures are rather variable from prevailing sutured to granoblastic with very rare triple points. The texture of some samples is weakly anisotropic, and the grain boundary shapes vary from straight to curved and even some triple points. Under thin-section microscope observation, the general impression is that the analysed marbles present disequilibrium geometries due to contact metamorphism characterised by relatively high temperature and low pressure, which caused predominantly quick re-crystallisation of the carbonate phases. The modal proportion of the minerals Cal~50%, Pl~20%, Mic~20%, Ms~15% (for sample M-01), Cal~45%, Pl~20%, Mic~15%, Bt~15% & Ms~5% (for sample M-02) and Cal~55%, kfs~20%, Pl~15%, Bt~5%, Ms~5% (for sample M-03).

4.3. Quality and processing of marble and granite

Due to geologically wide occurrence, technological needs less investment and economically cheap, marble and granite dimension stone widely adopted in foundations, facings, dams, coastal defences, and retaining and water containment structures. Based on the physico-mechanical tests and petrographic results, the quality of both granite and marble deposits is good. Therefore, based on the results granite has low porosity and water solubility (silicates are less soluble than carbonates) as well as high in compressive strength and harness (from the Mohos hardness scale quartz and calcite. Similarly, marble has high porosity, polishing surface, and water solubility as well as low compressive strength and hardness. This implies marble should avoided for load-bearing masonry units and external pavements (due to the above characteristics when compared to the ASTM specification (geotechnical investigation and testing of rocks). Marbles have a higher degree of water absorption than granites, due to silicates (quartz) being less soluble than carbonates (calcite), this also correlated with standard specifications of ASTM. Marble has a very high degree of polish, making it highly recommended for use as a decorative stone, particularly for internal flooring and walls. According to several authors, in mineral extraction, dimension stone quarrying does not require sophisticated technology () and has the lowest environmental impact [,,,]. Despite this, the economic importance of the industry still affects nearby communities, causing noise and visual pollution, damage to biodiversity, and harm to the landscape, among other environmental issues [,].

An important aspect to be emphasized is the distribution of costs and incomes from mining, as it has a strong influence on the success of projects. This perception is crucial, given the influence of government and company policies on the assessment of both environmental and social impacts, corporate social responsibility, shared values, and relationships with the community []. Proposals aim at policies and actions that have the potential to improve businesses by reducing social-related costs and improving productivity. According to Kogel [], this resource has almost the same mining life cycles as other earth resources, including coal, kaolin, industrial minerals, and metals. Regarding the mining method, most granite and marble deposits worldwide are mined using surface mining methods, such as quarries. Surface mining is cost-effective and requires fewer workers to produce the same quantity []. An open pit is one of the most common surface mining methods used to extract marble and granite resources.

4.4. Market

Ethiopia's dimensional stone industry is truly a local business. Various types of natural stone are quarried and sold locally in raw, semi-finished, and finished products, with different markets requiring different quality characteristics. Currently, marble dominates rock production, with approximately 8,100 tons produced in 2004 compared to 170 tons of granite [] (). These stone products are commonly seen in many commercial buildings in Addis Ababa and regional cities such as Dire Dawa, Bahir Dar, Hawassa, and Mekele. An excellent example of the modern use of Ethiopian dimensional stone is the Sheraton Hotel in Addis Ababa, where locally produced stone like Dareti marble, Babile granite, Ambo sandstone, and ignimbrite from Addis Ababa is used for cladding, walkways, stairs, and tabletops [] (Fig. 3A). Similarly, white marble slabs are used in residential buildings in Nazreth [] (Fig. 3B). Ethiopian dimensional stone has good potential to capture external markets, with exporting raw blocks being the most common way to access international markets. From 2001 to 2003, Ethiopia exported marble, granite, basalt, and travertine to European markets while importing dimensional stone []. According to Ethiopian Customs, approximately 30 tons of dimensional stone were imported between 2000 and 2005 [].

4.5. Opportunity

Ethiopia's economic policy enables and encourages private capital investment in the mineral sector. The government is creating an environment in which domestic and foreign companies can participate in the development of the mineral industry. Ethiopian metamorphic rocks offer a variety of rocks that have already been exploited or have the potential to serve as important component resources in the future (Walle and Heldal, 2001). The gray and white marble of the western region has already undergone significant industrial development and now helps shape the appearance of building facades in Addis Ababa and other Ethiopian cities. There are still interesting possibilities both for the further development of industrial quarries in homogeneous marble deposits and for more exclusive types of exploration for export markets. To this end, the National Mining Corporation's efforts to export marble to China, Turkey, and Saudi Arabia are an attractive option. Although granite mining in Ethiopia is still in its infancy, increasing knowledge of the resource potential and improved mining methods could aid in positive development. However, so far the granite deposits located in central and north-south Ethiopia are generally the species facing intense competition in the international market. Vast deposits of post-tectonic granites in areas such as Negash, Adi Eleni, Adikelete, Borpuah, Kisadgaba, Embamadre, and Sebeya granite deposit offer excellent opportunities for future development. Similarly, excellent quality and quantity of marble exposures are in the central, western, and northwestern parts of the Tigray region, which are arranged based on their descending order and are widely used in the domestic market (). There are still opportunities to explore new resources in the region, perhaps the most important part of the region's building stone production is the use of volcanic rock for local housing and, near the capital, large-scale industrial construction. Such resources show great potential for providing superior construction materials cost-effectively and have the potential to be further developed.

5. Conclusion

The Tigray region has substantial potential for dimension stone and terrazzo production, with rich rock resources available. However, current investment levels are low, with only a few companies engaged in these industries. To stimulate investment, it's essential to involve geologists with expertise in rock properties, petrography, and rock strength, following standards such as BS, ASTM, AASHTO, and German DIN. This expertise can help diversify the economy, create job opportunities, and enhance the non-oil sector. The marble and granite reserves in Tigray exhibit fine-grained, compact structures and vibrant colors, demonstrating excellent polishing qualities. Their high quality is supported by compliance with international standards, suggesting a promising future for quarrying. With favorable recovery rates and the potential for sustainable annual production, the region's deposits are attractive as hard, compact dimensional stones. Structurally, these deposits remain largely intact, with minimal disturbances like shearing or deformation, indicating good quality. Some quartz veins are present near the surface, but their intensity diminishes with depth—this will be further verified during quarry development. The majority of deposits are accessible, located on gently sloping terrains and underlain by low-grade metamorphic rocks, simplifying excavation and operational conditions.

The geological and petrographic analysis of Tigray's dimension stone reveals a diverse range of high-quality materials suitable for both structural and decorative uses. Granite deposits are particularly notable for their durability, strength, and aesthetic appeal, making them highly sought after in the construction industry. Various granite types, such as Negash and Kisad Gaba, highlight the potential for local sourcing that meets modern architectural demands. The petrographic analysis emphasizes the importance of mineral uniformity and the absence of inclusions in ensuring commercial quality. Marble deposits in Tigray, with their diverse colors and textures, offer significant opportunities for artistic and architectural applications. Unique characteristics from locations like Dichenama and Naeder position the region to contribute effectively to the global natural stone market.

In conclusion, Tigray's dimension stone resources hold both geological significance and economic promise. By promoting sustainable extraction practices and utilizing local resources, the region can strengthen its position in the dimension stone industry while ensuring environmental care and community involvement. Future research and investments in this sector could further unlock Tigray's potential, paving the way for economic growth and development.